“It bugs me sometimes the way people think about technology for the developing world,” says Amos Winter. “People think you can cobble it together from scrap parts, and undergrads can make it in a semester, and you can give it away for free. And none of that is necessarily true.”

Winter is lately renowned for having created a wheelchair specially tuned to the needs of people in poor countries: sturdy enough for uneven terrain, nimble enough to negotiate the indoors. The idea emerged when he was an MIT grad student visiting Tanzania in 2005; within three years he’d worked up a prototype to take back for a test run. That’s when his real education began. The chair was too heavy, users complained. It was too unwieldy to use inside. It wasn’t stable enough on hills.

Winter learned an important lesson: “We can’t just sit in this lab and make something on the lab bench and bring it to Tanzania and think it’s going to work,” he says. “It never works that way.”

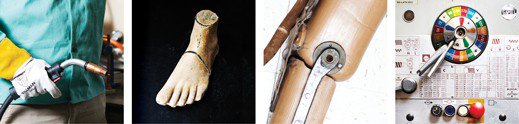

Now a professor of mechanical engineering at MIT, Winter applies that lesson to other projects. In a cluttered back room of his lab, he holds aloft a prosthetic leg and points to a locked metal coupling, which is, he says, the most commonly used knee joint in poor countries. “When you walk with this, you walk with a peg leg,” he says. “In most developing countries there’s a stigma associated with disability, and walking around with this is a clear sign that you’re disabled.”

Winter’s goal is to make a low-cost leg that copies the natural gait of $50,000 advanced prosthetics. “A lot of it just comes down to ‘Let’s make something that performs as good as the rich-world technology, for a small fraction of the price,’” he says. That typically means cheaper materials, but it’s not quite as simple as that. Those new materials need to be readily available in the country where the product will be made. They are likely to weigh less, or more, and behave differently under stress—producing a whole new set of engineering challenges. Winter describes, with great enthusiasm, the massive amount of calculation required to get the torque of the knee just right at every point in the walker’s stride.

He’s more than a year away from a working prototype, but he has already asked potential users in India what they might hope to do if they had a better leg. “The highest-ranked thing was to be able to sit cross-legged,” he says. “With existing prostheses, you just don’t get the rotational twist you need. And I never would have guessed that. This is why it’s so important to get there on the ground.”

Winter’s lab has the feel of a clubhouse; his students cheerfully mill about, and models and prototypes litter every tabletop. At the back end is a machine shop strewn with aluminum chips. You wouldn’t gather, at a glance, that these prototypes might touch anyone outside this room, but Winter talks about the “monumental potential for impact.” He gestures toward a mockup featuring a couple of plastic bins and some tubing: an experimental model of a drip irrigation system. To compensate for the often spotty power grids in poor countries, Winter’s version would use only a tenth of the pressure required by conventional systems and thus consume much less electricity. His system relies on an engineering trick involving plastic tubing that mimics the action of bronchia in lungs.

“If we crack this, and I think we’re going to, this is a billion-person problem,” he says. “Megafarms in Iowa can use this technology as well.”

—Timothy Maher